Constructing foundations on sites with restricted access can be one of the most challenging aspects of a building project. Tight working areas, limited machinery access, sensitive surroundings, or existing structures can make traditional excavation and concrete foundations impractical or impossible.

At Ultimate Screw Piling Ltd (USP), we specialise in foundation solutions for challenging environments. One of the most effective systems we use for restricted access foundations is our Mini Screw Pile range, designed to deliver reliable structural support where conventional methods fall short.

Restricted access foundations refer to foundation systems designed for sites where space, access, or environmental constraints prevent the use of standard construction methods. These challenges commonly arise on:

Tight residential plots

Rear garden extensions

Confined urban developments

Indoor or low-clearance environments

Sites with sensitive landscaping or surroundings

In these scenarios, foundation solutions must be adaptable, low-impact, and capable of being installed with minimal disruption — without compromising performance.

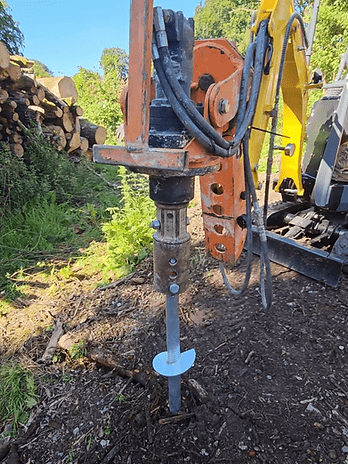

Mini Screw Piles are compact, steel foundation elements that are screwed directly into the ground to provide immediate load-bearing support. At USP, we use 50mm diameter Mini Screw Piles, engineered to perform effectively in restricted access environments.

Each starter pile is available with 5-inch, 6-inch, or 7-inch helices, allowing the pile configuration to be tailored to ground conditions and loading requirements. Once installed, extension shafts are added to achieve the required depth. These may be plain shafts or fitted with additional helices where increased bearing capacity is required.

In most cases, Mini Screw Piles can reach depths of 4.8 to 6 metres, depending on soil type, torque capacity, and site constraints.

Mini Screw Piles are particularly well suited to restricted access foundations due to their flexibility and minimal installation requirements.

Mini Screw Piles can be installed using compact machinery or, in some cases, by hand. This allows access through narrow gateways or confined spaces where larger equipment cannot operate.

Unlike traditional foundations, screw piling requires no large excavations, concrete pours, or spoil removal. This significantly reduces disruption to surrounding structures and landscaping.

Once installed, Mini Screw Piles are immediately load-bearing. There is no curing time, allowing construction work to continue without delay.

Mini Screw Piles can be configured to suit a wide range of soil types, making them a versatile solution for sites with variable or challenging ground conditions.

At USP, we tailor the installation method to suit each site’s access limitations and ground conditions.

For very tight access sites, we use mini or micro diggers capable of navigating narrow spaces while still delivering sufficient torque for standard installations. Ground conditions play an important role in achievable depth and performance.

Clay and made ground are generally well suited to screw piling. Chalk-heavy soils can present challenges, but these can often be overcome through pre-augering, allowing the pile to reach the required depth and torque.

Where access allows, our 1.8-ton digger enables higher torque output and greater achievable depths. This increases load-bearing capacity while retaining the benefits of a low-impact foundation system.

All installations are supported by in-house structural calculations, ensuring a value-engineered solution tailored to each project.

Ground conditions have a direct impact on the performance of any restricted access foundation system.

Dense clays and compact sands provide higher resistance, increasing torque and load capacity

Soft clays, silts, and loose sands allow deeper installation but may require additional helices

Gravelly or mixed soils can be managed with appropriate helix configurations

High-density chalk may require pre-augering to achieve suitable embedment below the point of heave

Each site is assessed individually to determine the most effective Mini Screw Pile configuration.

During installation, USP continuously monitors torque values to assess pile performance in real time. Empirical torque correlation provides a reliable relationship between applied torque and load-bearing capacity.

This approach allows us to confirm performance during installation, reducing the need for over-engineering and providing confidence in the long-term integrity of the foundation.

In situations where machinery access is not possible, Mini Screw Piles can be installed manually using a hand torque head.

This method is ideal for:

Confined indoor spaces

Noise- or vibration-sensitive environments

Sites with zero mechanical access

While hand installation has limitations in depth and load capacity, it offers a valuable solution for the most challenging restricted access foundation projects.

Traditional foundations often require extensive excavation, concrete, and curing time — all of which can be problematic on restricted access sites.

Mini Screw Piles offer several advantages:

Faster installation, often completed within hours

Reduced labour and material costs

Minimal ground disturbance and waste

Immediate load-bearing performance

For restricted access foundations, screw piling provides a clean, efficient, and sustainable alternative to traditional construction methods.

At Ultimate Screw Piling Ltd, we specialise in delivering restricted access foundation solutions using proven screw piling systems. Our combination of engineering expertise, specialist equipment, and in-house calculations allows us to deliver reliable foundations in even the most challenging environments.

Whether your project involves a tight residential site, a sensitive location, or limited access constraints, our Mini Screw Pile solutions provide dependable, low-impact support.

Contact Ultimate Screw Piling Ltd today to discuss your project or request a quote.

Our team of experts will be happy to help you with any questions you may have, and to provide you with a free, no-obligation quote for your project.