Ultimate Screw Piling Ltd have developed a warranty backed screw piling solution that fits perfectly with commercial new build schemes.

Following the successful foundation design, supply and installation of nearly 2000 screw piles for a major UK house builder over two different new build schemes totalling 140 houses being built on our system.

USP have played a key role in changing the way the industry thinks about foundations, by bringing a sustainable foundation solution to the forefront of Engineers and Architects minds; bringing screw piling to the use of new build homes in the UK, making it a viable solution for new build homes.

The USP screw piling solution eliminates the need for CFA piling or Omega piling, thereby avoiding inflated mobilisation costs associated with heavy plant and machinery.

This approach negates the necessity for costly engineered solutions for temporary works designs, expensive sourcing of materials for piling mats, time-consuming and expensive concrete wash away processes, and the removal of spoil and contaminated piling mat material.

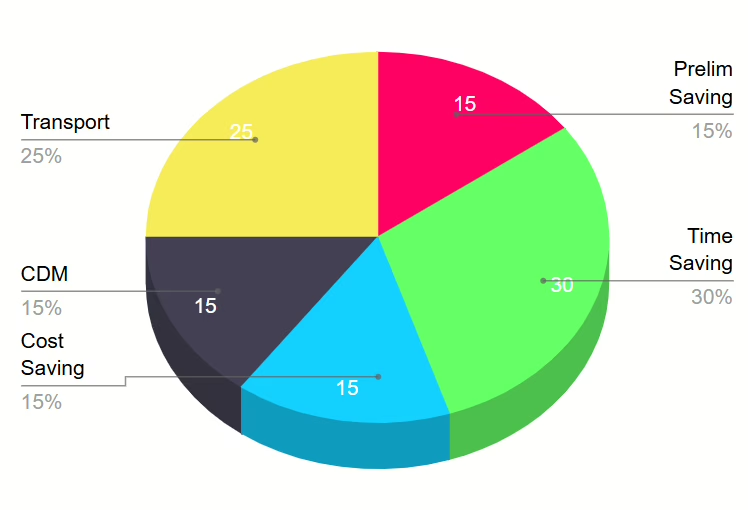

The USP solution provides a more time-efficient, cost-effective, and straightforward installation process that can reduce preliminary costs by up to 30% over the entire build life cycle of a project (site-specific).

This method ensures long-term efficiency, positively impacting the build programme for subsequent trades such as formwork, drainage, heave, rebar, slab pour, and superstructure erection.

USP provides a professional, warranted, coordinated design accredited solution for safer, cost-effective, time-efficient, and ergonomic construction processes across the country for foundations and RC slabs.

This includes the final test and commission process required for Build Warranty approvals. This approach is relevant in the current context of profit and loss constraints, carbon footprint reporting, and people management.

With full design approval from both building control and warranty, USP can reduce the risks associated with the foundation, slab, and management compared to traditional solutions.

Yes, USP screw piled solutions are fully approved by Premier Warranty and LABC Warranty.

Yes, a screw pile solution can be used on any size house.

Yes, screw piles can be used on any type of construction including traditional brick and block houses, timber frame, SIPs.

Yes, screw piles remove the need for mass excavation of trenches reducing huge bills for removal of muck away as well as increased reinstallation of concrete and any additional rebar that may be necessary.

NO, the only equipment required is an excavator with our torque head and measuring equipment attached. No piling mats required reducing prelim costs for the main contractor, offering a greener solution with less material on site and less movement on site. Reducing overall project CO2 rating. Screw piling also reduces risk elements on site as well.

Our team of experts will be happy to help you with any questions you may have, and to provide you with a free, no-obligation quote for your project.